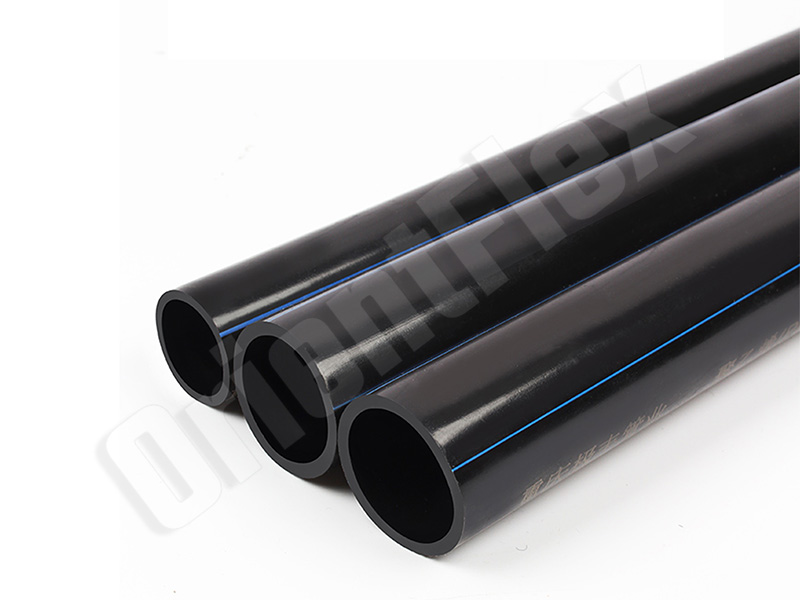

PE Pipe

PE Pipe

The PE pipe made from the PE materials, used as the water transport main and sub main pipe in the drip irrigation and spray irrigation system. No smell, long working life, easy installation.

Features

■ Good hygienic performance: No heavy metal salt stabilizer is added during PE pipe processing, the material is non-toxic, has no scaling layer, and does not breed bacteria, which well solves the hidden danger of secondary pollution of urban drinking water.

■ Excellent corrosion resistance: except for a few strong oxidants, it can resist the erosion of various chemical media; no electrochemical corrosion.

■ Long service life: Under rated temperature and pressure conditions, PE pipes can be safely used for more than 50 years.

■ Good impact resistance: PE pipe has good toughness and high impact strength, and heavy objects will directly press through the pipe without causing the pipe to break.

PE Pipe Specification

| Product Code | Diameter | Thickness | Length | Working Pressure |

| mm | mm | m | bar | |

| DRK2001 | 12 | 1.0 | 1000 | 4 |

| DRK0001 | 16 | 1.0 | 1000 | 6 |

| DRK0002 | 16 | 1.2 | 1000 | 6 |

| DRK0020 | 20 | 2.0 | 500 | 6 |

| DRK0021 | 20 | 1.5 | 500 | 6 |

| DRK0025 | 25 | 2.0 | 400 | 6 |

| DRK0030 | 32 | 2.0 | 260 | 6 |

| DRK0031 | 32 | 2.5 | 260 | 6 |

| DRK0040 | 40 | 3.0 | 160 | 6 |

| DRK0050 | 50 | 3.0 | 160 | 6 |

| DRK0051 | 50 | 4.0 | 160 | 6 |

| DRK0060 | 63 | 4.0 | 100 | 6 |

| DRK0061 | 63 | 5.0 | 100 | 6 |

| DRK0070 | 75 | 4.0 | 6 | 6 |

| DRK0080 | 90 | 4.0 | 6 | 6 |

| DRK0090 | 110 | 5.0 | 6 | 6 |

PE Pipe Advantage

(1) Reliable connection: The polyethylene pipe system can be connected by electric heating, and the strength of the joint is higher than that of the pipe body.

(2) Good impact resistance at low temperature: The low temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60°C. During winter construction, due to the good impact resistance of the material, the pipe will not be brittle.

(3) Good resistance to stress cracking: PE has low notch sensitivity, high shear strength and excellent scratch resistance, and its resistance to environmental stress cracking is also very prominent.

⑷ Good chemical corrosion resistance: PE pipes can withstand the corrosion of various chemical media, and the chemical substances in the soil will not cause any degradation to the pipes. Polyethylene is an electrical insulator, so it won’t rot, rust, or galvanically corrode; it won’t promote algae, bacteria, or fungal growth.

⑸Aging resistance and long service life: polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored in the open air or used for 50 years without being damaged by ultraviolet radiation.

⑹ Good wear resistance: The wear resistance comparison test of PE pipe and steel pipe shows that the wear resistance of PE pipe is 4 times that of steel pipe. In the field of mud transportation, compared with steel pipes, PE pipes have better wear resistance, which means that PE pipes have longer service life and better economy.

⑺Excellent flexibility: The flexibility of PE pipes makes it easy to bend. In engineering, obstacles can be bypassed by changing the direction of the pipes. In many cases, the flexibility of the pipes can reduce the amount of pipe fittings and reduce installation costs.

⑻ Small water flow resistance: PE pipe has a smooth inner surface, and its Manning coefficient is 0.009. The smooth performance and non-adhesive properties ensure that the PE pipe has a higher conveying capacity than traditional pipes, and also reduces the pressure loss of the pipeline and the energy consumption of water transportation.

⑼Easy handling: PE pipes are lighter than concrete pipes, galvanized pipes and steel pipes. It is easy to carry and install, and the lower manpower and equipment requirements mean that the installation cost of the project is greatly reduced.

⑽A variety of new construction methods: PE pipes have a variety of construction technologies. In addition to the traditional excavation method, a variety of new non-excavation technologies such as pipe jacking, directional drilling, liner, It is the only choice for some places where excavation is not allowed, so PE pipes are more widely used.

PE Pipe Connection

■ Electrothermal fusion: Use a special electric fusion welding machine to connect straight pipes to straight pipes, and straight pipes to pipe fittings. Generally used for pipes below 160mm.

■ Hot-melt butt joint: use a special butt welding machine to connect the pipes, generally used for pipes over 160mm.

■ Steel-plastic connection: it can be connected by flange, screw thread and other methods.

■ In order to facilitate construction and ensure construction quality, corresponding tools should also be prepared.

PE Pipe Packing

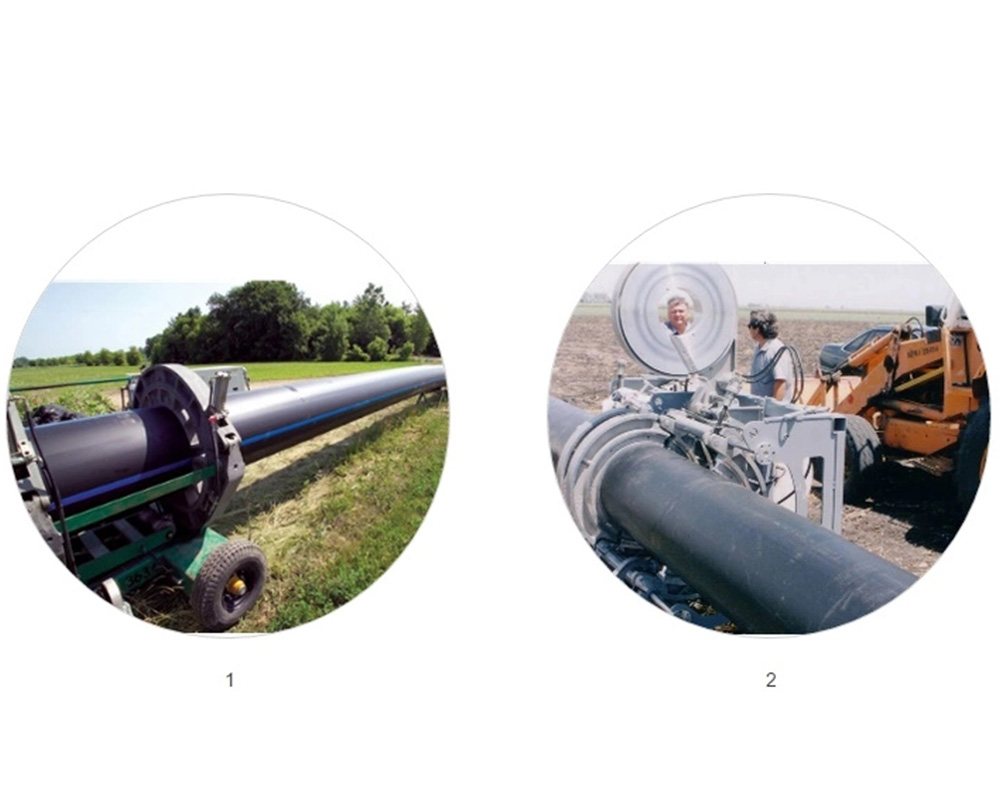

PE Pipe Application

PE agriculture irrigation pipe can be used in combination with drop arrows for potted plants; in combination with external tip-head, suitable for crops with unequal spacing. For example tree; Widely used in micro-irrigation projects, farmland water transport, aquaculture, building water supply

Related Products

Skype

orientrubber

Telephone

+86-311-68008301

+8618031853905

Visit Us

No.298 Zhonghua North Street ShiJiaZhuang, HeBei, China.